Glean Lean: How To Use Lean Approach In Service Industries?

Blog

This improved data can assist u.s.a. better predict failure, programme inspections in terms of time and coverage, and identify when inspections aren't necessarily the right solution for mitigation.

March/April 2022 Inspectioneering Journal

This study found that a automobile learning model was able to predict degradation rates for a hydrocracker unit more accurately and with a smaller margin of error compared to current industry practices.

September/October 2021 Inspectioneering Periodical

In this article, the author shares a couple of examples for RBI practitioners that will hopefully spur you on toward excellence in RBI modeling.

September/Oct 2021 Inspectioneering Journal

Inspectioneering and Height co-hosted the seventh bi-annual Meeting of the Minds with a select group of mechanical integrity experts from across the industry. The meeting focused on piping RBI and the challenges operators are facing implementing information technology.

Blog

The results of the analysis demonstrate the heady possibilities for how "Big Information" can be used to empower the reliability and corrosion engineer to solve real-globe reliability challenges faster and more accurately than current manufacture...

Authors:

Partner Content

Our proprietary furnace tube inspection arrangement, FTIS is an ultrasonic inspection technology capable of rapid, automated fired heater coil inspection in refinery fired heaters. The data captured by our furnace tube inspection organization is...

Blog

Acting as a reliability twin, QRO is a new dynamic reliability arroyo that bridges existing first principles-based reliability models with advanced data scientific discipline principles and arrangement-based optimization to bulldoze improved facility performance.

Authors:

July/August 2021 Inspectioneering Journal

This article examines the quantitative tank RBI method found in API 581 and discusses uses for tank RBI other than deferral of scheduled internal inspections.

July/August 2021 Inspectioneering Journal

A risk management arroyo for relief valves should be able to determine the proper interval of maintenance events and the necessity of installing isolation valves, rupture discs, or 100% spare chapters.

May/June 2021 Inspectioneering Journal

This commodity describes an owner-user'southward evergreening procedure to maintain authentic data to back up the mechanical integrity program and assist in planning inspections, turnarounds, repairs, replacements, and upgrades.

May/June 2021 Inspectioneering Journal

This article discusses how Quantitative Reliability Optimization (QRO) tin can help empower reliability and operations leaders with better information to brand smarter and more confident reliability decisions for their facilities.

Partner Content

LOTIS utilizes light amplification by stimulated emission of radiation profilometry to conduct internal steam reformer tube inspections. The data captured past LOTIS is exceptionally powerful when combined with our LifeQuest™ remaining life assessment capabilities, providing an integrated...

March/April 2021 Inspectioneering Periodical

This article provides insights into the AIV harm mechanism, reviews approaches to calculate the probability of AIV failure in piping, provides design practices to forbid AIV failure, and introduces a RBI arroyo to evaluate gamble of AIV failures.

Web log

Have yous ever wondered why, fifty-fifty though inspection reports are one of the primary keys to a good MI plan, they are so rarely reviewed? I of the things I always observe when reviewing a programme is the lack of concise inspection history.

January/February 2021 Inspectioneering Journal

This article discusses the header specification, design, fabrication, and inspection processes to identify where opportunities were available to proactively address the vulnerabilities that resulted in the header rupture.

September/October 2020 Inspectioneering Journal

Implementing RBI equally part of a Mechanical Integrity organisation at dissimilar sites is not a uncomplicated copy and paste projection. Each instance has its own characteristics and challenges. This commodity describes implementation in two vastly different facilities.

September/Oct 2020 Inspectioneering Journal

This article discusses some of the common roles of the RBI team and provides a glimpse of an RBI plan gap assessment, while offering helpful communication for comeback.

Partner Content

InVista is a lightweight, manus-held ultrasonic in-line inspection tool (intelligent pig) capable of detecting pipeline wall loss and corrosion in unpiggable or hard-to-audit pipelines. The pipeline geometry inspection data captured by the...

July/August 2020 Inspectioneering Periodical

Inspectioneering chats with Gecko Robotics near the new rapid ultrasonic gridding technique and how it tin can exist utilized to increase the speed and effectiveness of equipment inspections.

July/Baronial 2020 Inspectioneering Journal

This article explores the API RP 581 tertiary edition approach to HTHA harm factor calculations to obtain a probability of failure that subsequently affects hazard. Sample calculations are provided to assert an understanding of the concept.

May/June 2020 Inspectioneering Periodical

The commodity describes the results from a recent CUI Joint Industry Project which resulted in an RBI methodology for managing the CUI threat. The methodology assesses iv CUI barriers: material, blanket, water wetting, and design.

November/Dec 2019 Inspectioneering Periodical

I have been involved with risk-based inspection and risk-based piece of work process development for much of my career. The i matter I accept learned equally I've walked this path is that the concept of 'risk' extends far beyond our manufacture.

September/October 2019 Inspectioneering Journal

The writer discusses a method being used in most of their refineries and petrochemical facilities that allows them to optimize the scope of NDT during turnarounds, while improving the reliability of bundles.

Partner Content

Information technology's a scary thought to call up that with all the new advancements in technology, some facilities still rely on traditional inspection contractors that perform out of date procedures. Y'all rely on engineering science to proceed your home and identity safe, so...

Blog

Here is four-step process for developing effective and efficient piping management strategies that tin can help optimize costs, refocus resources, and reduce risk.

Authors:

Blog

Developing a comprehensive turnaround (TA) work scope for process equipment is a critical step for achieving a facility'southward business concern goals. Risk Based Piece of work Pick is a proven process for prioritizing and optimizing planned work for an impending TA.

Weblog

Take a chance Based Work Pick (RBWS) is an industry all-time do used to assist refiners ameliorate-manage the safety and reliability of operations for a facility. When properly conducted, RBWS can help refiners optimize major turnaround projects.

July/Baronial 2019 Inspectioneering Periodical

This case study is intended to demonstrate how a Qualitative Risk Assessment can be a cost-effective and resource-efficient means to prioritize equipment which is oftentimes "under the radar".

May/June 2019 Inspectioneering Journal

A well-implemented and managed reliability program incorporating RBI, DMR, and IOWs can identify potential harm mechanisms, optimize maintenance and inspection activities, reduce risks, and improve the governance in managing Ethane Crackers.

Partner Content

How long does information technology take for you to receive reports afterwards an inspection has been completed? A week? A calendar month? Does the information come from multiple sources with no way of knowing if it has been manipulated? Traditional inspection contractors do non have...

Blog

This is the first commodity in a new column. In each article, the author will share technical, thought-provoking, and sometimes humorous or emotional experiences garnered in a career that spans over 20 years inside the gates of facilities.

Blog

Corporations at present have the flexibility to choose RBI software from vendors offering a diverseness of tools and features to keep track of calculations, records, and information. This infographic shows 11 things you should consider when selecting an RBI software.

Blog

Over the concluding six months, Inspectioneering has released a plethora of interesting and educational content that has been read more than than 150,000 times online. In case you missed it, here'south a recap.

Blog

This blog volition walk through practical steps for managing IOWS and volition demonstrate what successful IOW management can await like.

Authors:

March/April 2019 Inspectioneering Journal

This commodity shares some benefits of pro-actively performing RBI assessments during the design and construction phase of the establish with professionals involved in stock-still equipment mechanical integrity programs.

Partner Content

Equity Engineering science Practices® (EEPs) are a collection of detailed & customizable Best Practices integrated with a customizable management organisation. EEPs include: 650+ branded and customizable Best Do Documents, 225+ Pre-Engineered &...

January/February 2019 Inspectioneering Journal

An effective RBI system implementation results in, non only safeguarding your assets & people, simply can likewise reduce unnecessary inspection activities that may be required due to conventional & nonsystematic approaches.

Weblog

The 2019 API Inspection and Mechanical Integrity Summit will be boot off subsequently this calendar month in Galveston, TX. This four-twenty-four hours event will begin with 14 high level preparation courses offered Mon, Jan 28th, and so a height notch conference and...

November/December 2018 Inspectioneering Journal

This article shares examples of where RBI piece of work processes either broke down or were non-existent, or where the user did not fully sympathize the technology or overall RBI logic and the results.

Nov/Dec 2018 Inspectioneering Journal

This article discussed the importance of an asset direction philosophy that integrates software, maintenance tools (RCM, FMECA, RBI, PM, and PdM), data collection, and analytics to improve and optimize asset direction through emerging technologies...

November/December 2018 Inspectioneering Journal

This article provides an overview of the key components in establishing IOWs, the levels of IOW limits, and the basic principles and awarding of API Recommended Exercise 584 to achieve reliable fired heater performance.

Partner Content

Training options to meet your needs. Eastward²M contracts with API to deliver grooming programs for FFS, Risk–Based Inspection, Damage Mechanisms, and Pressure Relieving Systems. ETI and Customized Grooming offers specialized courses based on manufacture...

September/Oct 2018 Inspectioneering Periodical

This commodity presents a management arroyo for the implementation of Integrity Operating Window (IOWs) nether API RP 584 and discusses the IOW planning process and how input from other programs like RBI and Corrosion Management Plans is critical to...

July/August 2018 Inspectioneering Periodical

Software implementation, including RBI, comes with a lot of ad-hoc challenges and pitfalls. In that location are numerous options for RBI software currently available, and they may differ past blueprint, purpose, role, scope and capabilities. This article...

May/June 2018 Inspectioneering Journal

Every bit assets age and production demands grow, it becomes increasingly critical to implement sustainable long-term AIM strategies and programs. This article dives into the elements that will help ensure the successful management of assets throughout...

May/June 2018 Inspectioneering Journal

This commodity intends to use a top-downwards approach of describing RBI methodology and how it fits in a facility management arrangement. The main idea of this article is to provide a comprehensive picture of RBI methodology in terms of nuts, technology...

March/April 2018 Inspectioneering Journal

As RBI continues to proliferate beyond industry, there are notwithstanding those that are reluctant to transition from a fourth dimension-based to gamble-based inspection arroyo - especially in the upstream oil & gas business. These 4 benefits might help to lessen the...

Partner Content

What practice you demand: CONSULTING - Bailiwick matter experts, consultants, or team of highly skilled engineers to aid solve my problem. SOFTWARE - My team requires software, products, or resources that will solve the problem. Preparation - I require...

March/Apr 2018 Inspectioneering Journal

Implementing RBI for process piping tin be a very dull and lengthy practice, especially for major process plants with thousands of feet of interconnected piping. This article shares the experience of ADNOC LNG following a structured RBI approach...

January/February 2018 Inspectioneering Journal

Most of u.s.a. that work integrity and reliability empathize what we do and how nosotros practise it. But how many of us understand WHY we practise things? Understanding the motives behind our activities, initiatives and programs can help to galvanize and lay a...

September/Oct 2017 Inspectioneering Periodical

The challenges companies face when implementing an RBI plan from scratch tin make the exercise seem daunting. To ensure that implementation is completed smoothly and the benefits of RBI are apace realized, at that place are considerations that should...

July/August 2017 Inspectioneering Journal

Establishing risk targets is an important attribute of any gamble-based inspection (RBI) program and is a requirement of API RP 580. Metrics and consistency are important considerations for those using RBI to measure and manage risks equally part of their...

May/June 2017 Inspectioneering Journal

Steam systems account for virtually a third of the energy used in industrial applications for production output. Maintaining their integrity and efficiency is vital. Learn how an effective risk-direction process aids in the optimization of these critical...

Partner Content

Becht's industry-leading Corrosion and Metallurgical experts are here to assistance with significant owner-operator experience covering the refining, petrochemical and chemical industries. This expertise is leveraged to assistance our clients become more...

March/Apr 2017 Inspectioneering Journal

This article discusses the utilize of the RBI methodology supplemented past a well-designed IOW plan to assess and manage aging in fixed equipment and piping in hydrogen generation units.

January/February 2017 Inspectioneering Journal

Historically, if asked when or how probable an austenitic serial stainless steel component is to crevice, the usual answer was "very" or "possibly" or, later, "I didn't encounter that coming." With API's new risk assessment methodology, the...

January/February 2017 Inspectioneering Periodical

Evaluating remaining wall thickness of an asset is not enough to ensure its continued safe operation. Proactive strategies should be implemented to assess the unabridged environment affecting an nugget's status, including the development of more...

January/Feb 2017 Inspectioneering Journal

This article presents a perspective on the human factor and emphasizes the value of using hazard tools at all levels in the system to assist provide management focus during times of severe economic pressure level.

November/December 2016 Inspectioneering Journal

This article summarizes 7 key questions that an organization needs to answer to create a robust mechanical integrity program that is properly designed to monitor corrosion and indicate when issues increase to a level requiring review or...

Partner Content

Squad's integrated affect signal corrosion program manages all aspects of the integrity process from screening for damage to permanent repair assuring integrity – every fourth dimension. TEAM'southward unique plough-key approach to touch betoken corrosion integrity...

November/Dec 2016 Inspectioneering Periodical

Human factors, inspection effectiveness, and RBI all play an important role in running an constructive asset direction programme. This article discusses how each is applicable to inspecting equipment in processing facilities.

November/December 2016 Inspectioneering Periodical

This newspaper provides the groundwork for the applied science behind the 3rd Edition thinning model every bit well as step-by-step worked examples demonstrating the methodology for thinning in this new edition of API RP 581.

September/October 2016 Inspectioneering Journal

Risk-based inspection (RBI) programs and processes are front and center, both as a claiming to get it right, and equally an integral tool and process to help us achieve success in risk direction and equipment reliability. It has to be implemented,...

September/October 2016 Inspectioneering Journal

Integrity and reliability personnel at processing facilities are no strangers to initiatives to ameliorate processes in the pursuit of establishing all-time-in-class reliability programs. It is common practice for operators to enlist help from third...

Blog

Over twenty years ago, in the January/Feb 1996 issue of Inspectioneering Periodical, we invited readers to participate in a brief survey concerning industry and non-manufacture topics. We recently unearthed the results to this survey and I thought our...

Partner Content

Squad provides full inline, onsite and, shop valve repair services and maintenance programs for near all valve types, brands, sizes, materials, pressures, and operating conditions, including actuators and operators. Our valve repair solution is...

July/Baronial 2016 Inspectioneering Periodical

Turnarounds operate at a different pace than routine work. Near found-based inspection departments have historically struggled with Turnaround certificate control, such as integrating contractor reports into their routine information management system. Our...

July/August 2016 Inspectioneering Periodical

Many plants inspect PRDs on preset intervals as recommended past inspection code API 510, and implement inspection practices such as API RP 576. Only seeking PRD compliance with codes and standards usually results in mediocre mechanical integrity and...

Blog

Anyone who knows me knows that Take a chance Based Inspection (RBI) and Chance Management are true passions of mine. I have dedicated much of my career to studying them, understanding their intricacies, and witnessing the benefits of their successful...

Blog

Here are v mutual misconceptions about RBI that should not prevent you from gaining a more advanced agreement of the true state of your site's equipment. After all, the more we know, the better we can manage equipment integrity and brand...

May/June 2016 Inspectioneering Journal

RBI and NII are designed to achieve significant price savings and risk mitigation benefits over a slice of equipment's lifetime in the long term.

Partner Content

TEAM believes that quality inspections are the key to reliability. Our inspection crews are made upward of specialty trained, experienced technicians who adhere to the highest quality standards. Our API 653 inspectors deliver thorough, reliable...

Blog

When was the last time y'all reviewed your Risk-Based Inspection (RBI) methodology? Are you using calculation procedures for probability of failure, effect of failure, and risk that haven't had their ground reviewed in years?

March/April 2016 Inspectioneering Journal

Achieving fired heater reliability in conjunction with coming together performance standards tin can be a challenging feat. Operation is a measure of the degree to which the fired heater is in an operable status at any given time.

Online Article

Updated editions of both API 570 and API RP 580 were recently released by the American Petroleum Institute.

January/February 2016 Inspectioneering Periodical

The enormous reject in oil prices over the past 14 months has definitely slowed projects and changed the energy and product landscape. Despite this, refineries, petrochemical plants, and chemical facilities must continue to run safely,...

January/February 2016 Inspectioneering Periodical

Pipeline direction remains fraught with condom risks for operators and the environment. Last year, the Ontario Energy Board determined that a $12 billion oil pipeline proposed by TransCanada Corp. would pose more risks than rewards for the province.

Partner Content

Statistical techniques are meant to complement the work of SMEs and can provide deeper insights into the inspection information collected as part of a reliability program. Pinnacle has combined traditional methods, expertise, and Machine Learning to...

Online Commodity

Offshore platforms pipelines, terminals and downstream facilities, are plush to build, operate and maintain, then it's imperative that operators proceed tight control over the total life-cycle cost of all associated equipment.

July/August 2015 Inspectioneering Journal

Asset managers demand to know when repairs and replacement are required for many reasons, including safe operation, authentic budgeting, replacement planning, and on-going reliability. When predicting design life based on a simple, linear corrosion...

May/June 2015 Inspectioneering Journal

Assessing take a chance is an integral part of working at a refinery. Infrastructure supporting the miles of piping, process vessels, and the platforms and ladders used in daily unit operations are often taken for granted. The Civil Structures Management...

March/Apr 2015 Inspectioneering Journal

Today, many managers are finding that they can address the reliability of all types of assets past combining RBI and Reliability Centered Maintenance (RCM) processes together into one comprehensive reliability management process.

Jan/Feb 2015 Inspectioneering Journal

Challenges abounded in 2014 for the process industries, and information technology does not look like they will let upward presently. But then again, that'due south life, every bit they say. Afterwards xl years in the manufacture the old adages all the same ring true, "there is nothing new under the...

Partner Content

Pinnacle'due south data-driven reliability framework ensures the correct information is fueling the right intelligence, helping you make confident, strategic decisions.

Blog

I recently received an research about performing gamble-based inspection (RBI) at the design stage of a unit. More specifically, I was asked if information technology was possible to start an RBI project in the Front End Engineering Design (FEED) phase even though the...

Nov/December 2014 Inspectioneering Journal

Today, more than than ever, refinery operators are focused on maintaining safe operations for their employees and extending the life cycle of valuable operating equipment to optimize efficiencies and avoid expensive unforeseen shutdowns. When process...

Blog

One of the most significant advancements to come forth in the fixed equipment mechanical integrity (FEMI) business in the past two decades is the awarding of take chances-based inspection (RBI) for inspection prioritization, planning, and scheduling. The...

May/June 2014 Inspectioneering Journal

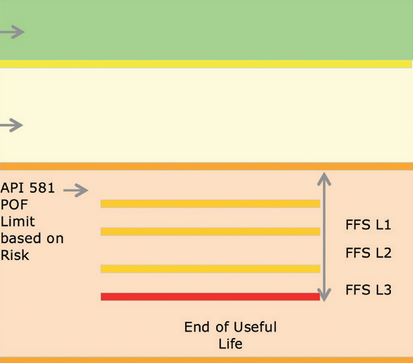

As an RBI consultant, I frequently get involved in discussions spawned from a misunderstanding of the relation between Take a chance Based Inspection (RBI) approaches and Fettle for Service (FFS) assessments. Questions similar: If thickness is below the...

Blog

A paper was presented at the 68th Conference of the Italian Thermal Machines Engineering science Association entitled Updated Failure Rates and Risk Direction in the Process Industries. It was presented in October 2013 by INAIL, an Italian insurance...

Partner Content

Download Summit'south Economic science of Reliability Written report - Refining to come across how reliability is affecting profitability.

Blog

Occasionally, nosotros similar to provide recaps of articles written past our authors on a specific subject related to asset integrity management. This week, we're highlighting four of our most popular articles written nigh storage tank inspection.

Blog

Is it possible to develop an internal RBI program without depending on third-political party/commercial software?

Blog

Those of y'all who have followed Inspectioneering for any amount of fourth dimension understand that nosotros publish a vast amount of content dealing with chance based inspection (RBI) methodology. Ever since information technology was get-go developed and used in the procedure industries,...

September/October 2013 Inspectioneering Journal

Maintaining the mechanical integrity of above footing storage tanks (AST's) is the focal betoken of tank inspection programs. Performing internal inspections is an integral part of a tank integrity plan, nevertheless, deciding when to accept a tank out...

Web log

We've been discussing Scalable Accuracy and its use related to Lifecycle Direction technologies available to owner/operators. The last few topics have included Gamble Based Inspection, Fitness for Service using Accuracy, the approach for Equipment...

Partner Content

Traditional pressure vessel inspections often crave taking avails out of service. However, MISTRAS' Not-Intrusive Inspection (NII) programs provide data as good or better than internal inspections, while assets remain in service. NII is...

Blog

We've been discussing Scalable Accurateness and its employ related to Lifecycle Management technologies available to possessor/operators. The terminal few topics accept included Fitness for Service using Scalable Accuracy, the approach for Equipment Lifecycle...

Blog

Standing from final week's blog, I want to become in depth into scalable accuracy for fixed equipment lifecycle management. In this mail service, I want to outline the scalable accuracy approach to fixed equipment lifecycle management.

Web log

Continuing from last week'due south blog, I want to get in depth into scalable accuracy for fixed equipment lifecycle management. In this post, I desire to outline the scalable accurateness approach to stock-still equipment lifecycle management.

Weblog

In the next few blog posts, we volition be going in depth on scalable accurateness. This postal service walks through the thinking needed prior to initiating. Then we volition discuss ii technologies immediately available to plant operators for stock-still equipment...

Blog

This post is the last in a series almost Risk Basked Inspection (though, of grade, this will not exist the last fourth dimension I discuss RBI). The before posts were on reasons for RBI, defining risk, and on managing risk. In this post, I want to talk well-nigh...

Partner Content

Traditional, paper-based inspection processes can prevent plants from being equally effective as they can be. By digitalizing your mechanical integrity process and data with MISTRAS Digital®, plants accept realized up to 75% gains in IDMS information entry and...

Blog

This is the third of four blogs in a series about Take chances Based Inspection (RBI). You tin read the previous blogs on a history and reasons for RBI and on starting to define risk. This mail service deals with the 2nd one-half of the equation used to define...

Blog

This is the second of four weblog posts on Risk Based Inspection, or RBI. The first post covered a cursory history and started the discussion on why you lot would want to utilize RBI. The adjacent footstep is defining hazard.Â

Blog

Anyone who knows me knows that Take chances Based Inspection (RBI), and Run a risk Management, are a passion of mine, so my next few posts will feature these topics. These are not all-inclusive, but Inspectioneering.com has dozens of articles and you can...

May/June 2013 Inspectioneering Journal

1 of the reasons we continue to accept also many fixed equipment mechanical integrity (FEMI) events in the refining and process industries is the lack of understanding and appreciation past site management for the hazards posed by the 101 FEMI problems.

May/June 2013 Inspectioneering Journal

Industrial furnaces are used extensively throughout the unabridged oil and gas manufacture, too equally other procedure industries such as pulp and paper, metals and mining, chemical, and petrochemical. An industrial furnace, or directly fired heater, is a...

Partner Content

Antea delivers highly flexible risk-based nugget integrity software with 3D Digital Twin integration to optimize maintenance, reduce risk, and improve mechanical integrity for oil and gas, power generation, and chemical plants and facilities. Whether...

Weblog

This is my second of three posts on Cardinal Performance Indicators (KPIs) based on requests and discussions on the issue.  In part 1 of this series I provided a brief overview of KPIs and their ability to predict good, poor, and sometimes...

Blog

This is a question with which I frequently like to starting time the API RBI 580/581 grooming course when I am instructing. It is meant to provoke the attendees to actually recall difficult about why they order an inspection or really think about inspection...

November/Dec 2012 Inspectioneering Periodical

As refiners keep operating aging infrastructure, safe operation and equipment availability continue to exist key components of a sustainable operation. When considering optimizing inspection projects, more than and more refiners are making Risk-Based...

September/October 2012 Inspectioneering Journal

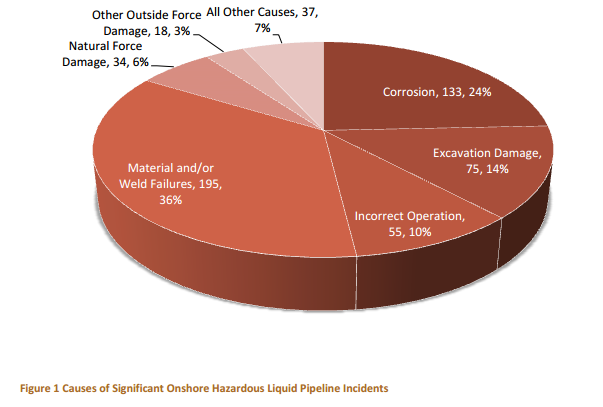

Pipage failures still represent a frustrating and ongoing trouble for processing plants (example in Figure i). Failures are commonly reported and contribute to large losses. Also per the author'due south experience, piping still represents the...

July/August 2012 Inspectioneering Periodical

The question of how to prepare risk targets is a logical one and should be addressed prior to or in the very early stages of RBI implementation. This article will guide readers through the basic elements required to address this question within an...

Partner Content

Tri-Lateral Phased Array is a novel robotic phased array ultrasonic testing technique for the on-stream inspection of fixed equipment in wet hydrogen sulfide (H2S) service. TriLat identifies and quantifies moisture H2S damage in the base metallic of...

March/April 2012 Inspectioneering Periodical

Air-cooled rut exchangers (AC-HEs) are used extensively throughout the oil and gas industry, from upstream product to refineries and petrochemical plants, under high force per unit area and high temperature weather condition, as well as corrosive fluids and...

January/February 2012 Inspectioneering Journal

The diverse factors of the claiming, eastward.chiliad. creating effective and then efficient inspection strategies, are at the crux of the decision process. Within each of these factors are questions that must be answered. The answers should be well thought...

November/December 2011 Inspectioneering Journal

The original commodity on scalable accuracy which laid the groundwork for the concept was published in the March April 2011 issue of the Inspectioneering Journal, entitled Scalable Accuracy, Key Roles of Risk Based Inspection and Fettle for Service,...

September/October 2011 Inspectioneering Periodical

Maintenance has been effectually since prehistoric human fixed a broken, trusted spear instead of fashioning a new one. One concept of maintenance is any activity that extends the useful life or enhances the performance of an item of interest. A wide...

March/April 2011 Inspectioneering Periodical

Due to increasing market demands for stabilized crude, it is a high priority for oil handling and processing facilities to avert production interruption. Ane optimization opportunity is to review our approach for scheduled facility Exam and...

Partner Content

Olympus' OmniScan™ X3 64 phased array and TFM flaw detector is equipped with enhanced phased capabilities and even faster TFM. The rugged and portable instrument features powerful 64-element probes with a 128-aperture TFM. Backed by its high...

March/April 2011 Inspectioneering Journal

Two technologies, immediately available to plant operators for stock-still equipment life-cycle management are Gamble-Based Inspection (RBI) and Fitness for Service (FFS), 2 best practices that optimally work together or can standalone. Both have...

November/December 2010 Inspectioneering Journal

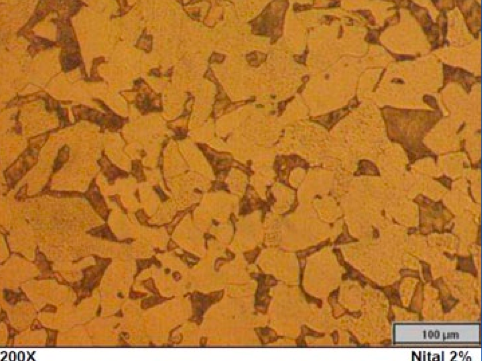

Understanding, predicting, detecting and controlling high-temperature hydrogen set on (HTHA), accept been elusive goals of materials engineers and scientists for over seventy years. The destruction of low alloy steel components exposed to hydrogen through...

September/October 2010 Inspectioneering Journal

In the first article in this series entitled How to Put It All Together - Guide to Organizing a Successful PEI Program, (1) I provided an overview of the necessary Management Systems (MS) for a successful program to reach excellence in pressure...

July/August 2010 Inspectioneering Journal

Inspection intervals for equipment take in the past been divers in a prescriptive mode. However, manufacture is at present embracing the Take chances Based Inspection (RBI) approach which in contrast prioritises inspections based on an assessment of the risk to...

May/June 2010 Inspectioneering Journal

This article describes the API Risk-Based Inspection (RBI) methodology for pressure relieving devices (PRDs) every bit detailed in the presently to be released second edition of API 581 "Base of operations Resources Document On Risk-Based Inspection" This methodology has been...

July/Baronial 2009 Inspectioneering Periodical

In the current economic environment, there is increasing pressure on petrochemical refineries and delivery systems to exist more productive and to minimize unscheduled shutdowns due to leakage. Leakage can occur from either the pipage itself or the...

May/June 2009 Inspectioneering Periodical

In the oil and gas manufacture, pressure vessel integrity is a major concern. After internal and external inspections diverse anomalies or defects can be reported and repairs could be required for pressure vessels in gild to restore its original...

May/June 2009 Inspectioneering Journal

This article is Role 3 of a 3-Role series. The articles in this series provide a step-past-step case of utilization of API RP 581 and build off of each other. This article (Part 3) will encompass the final chance analysis, inspection planning, provide a...

March/April 2009 Inspectioneering Journal

The previous article (Part one) covered Probability of Failure (POF), including modeling of thinning and stress corrosion cracking and demonstrated how API RBI provides credits for past inspections, because their effectiveness in detecting those...

January/February 2009 Inspectioneering Journal

This commodity provides a unique opportunity to guide the reader through API RBI quantitative calculations per API RP 581, Second Edition, September 2008, using real data. The author guides you step by step from input data to final answers including,...

July/August 2008 Inspectioneering Journal

The following is an interview with Scot Haines, (Corrosion Engineering Advisor). The IJ wishes to thank Scot and the Hess Corporation for taking the time to share with the "IJ" community.

May/June 2008 Inspectioneering Periodical

Exercise we know how to free ourselves from the electric current level of thinking to ascension to a higher level? It volition take this for us to overcome many of our current challenges in the arena of equipment reliability.

November/Dec 2007 Inspectioneering Journal

Facilities are often content in compiling consequence data, inbound thickness measurements, assigning a system description, tracking work requests and recommendations in their databases. These are certainly valuable data points but using your database...

Nov/December 2007 Inspectioneering Journal

Over the past 18 years of serious RBI involvement, it has become clear to me that in that location are certain hurdles, that when "cleared", have paved the fashion to jurisdictional credence of RBI (and fettle for service, for that thing). This article will...

September/October 2007 Inspectioneering Journal

In my travels effectually the world equally one of the primary API RBI 580/581 training grade instructors the question always comes up, "What hazard threshold or tolerable hazard should I exist using?" and "If I practice not take i, how can I implement RBI?"

May/June 2007 Inspectioneering Periodical

This is office 2 in a multi-role series. Part ane set the stage in explaining the basics of RBI. Every bit I am most familiar with API Base Resources Document 581, I will continue to utilize this technical ground for this commodity.

May/June 2007 Inspectioneering Journal

From fourth dimension to time, I'k asked why some operating sites don't seem to pay adequate attention to the need to protect and preserve pressure equipment integrity (PEI). Too frequently a few sites don't seem to "get it" until they accept a major process safety...

March/April 2007 Inspectioneering Journal

An before version of this updated article appeared in the January-February 1998 consequence of the Inspectioneering Journal. It is difficult to believe that nine years have passed so quickly. Fortunately the industry, every bit a whole, has learned much and...

November/Dec 2006 Inspectioneering Journal

On July 26, 2006, the Country of California revised its Petroleum Safety Orders. The Petroleum Safety Orders are role of the California Lawmaking of Regulations Title eight and address the wellness and safety requirements for places of employment in the State of...

July/Baronial 2006 Inspectioneering Periodical

The Shell Martinez Refinery has been in functioning since 1915, and is located thirty miles northeast of San Francisco on almost ane,000 acres of state. The refinery combines country-of-the-art facilities and equipment to catechumen approximately 165,000 barrels...

May/June 2006 Inspectioneering Journal

Revisions to the California Code of Regulations Title 8 Petroleum Safe Orders are nearly consummate and the new regulations should exist published belatedly summer 2006. The regulations will bear upon both drilling and product facilities and refining,...

January/February 2006 Inspectioneering Journal

This survey did non make metrics the primary focus. More importantly, our focus was on practices that lead to better performance. You still have to link these practices to performance.

March/April 2005 Inspectioneering Periodical

Nosotros are happy to announce the x-year ceremony of the countdown effect of the Inspectioneering Journal!

November/December 2004 Inspectioneering Journal

Several new API inspection recommended practices be in which inspectors need to exist knowledgeable and qualified. This article details some of those standards.

July/August 2004 Inspectioneering Journal

The post-obit is the final part of a 2-function series outlining the human relationship between fundamental operating parameters and corrosion that has been used to develop a set of guidelines to define an operating envelope.

March/April 2004 Inspectioneering Journal

Data management is an important issue in today's world. We have data all over the place. Every director is looking for ways to migrate data from platform to platform to salvage on the cost of re-gathering data and ways to share output from various...

July/Baronial 2003 Inspectioneering Journal

"Depression Hanging Fruit" and "Step Change" are analogies that have been bantered around in our industries for some time. Picking the low hanging fruit is just the beginning and something that most passersby can glean. Also, real alter that affects an...

May/June 2003 Inspectioneering Journal

In that location are many aspects to successful, effective and efficient implementation of RBI i, such as; - Information collection - Operations data - Mechanical data - The role of inspection histories and inspection planning - How much data do I really demand to...

March/April 2003 Inspectioneering Periodical

The big LNG facility is located on DAS Isle, offshore of Abu Dhabi, in the Farsi Gulf and experiences extremely loftier humidity year round. These conditions are known to produce a high potential for external corrosion and under insulation...

November/December 2002 Inspectioneering Periodical

The Alberta Boilers Safety Association (ABSA) issued the requirements document, Gamble Based Inspection Programs for Pressure Equipment, in March 2001. This document defines the minimum requirements for the development and use of gamble based inspection...

September/Oct 2002 Inspectioneering Journal

In May 2002, after half-dozen years of preparation, the API published the first edition of API 580 Risk-based Inspection. The certificate is now an ANSI/API Standard, which was balloted and approved using the ANSI consensus procedure for creating American...

July/Baronial 2002 Inspectioneering Journal

Risk-Based Inspection (RBI) is an emerging technology available to plant engineers and managers as theyapply chance directed activities to prioritize piece of work and available resources for equipment management. This paper describes the learning of highly...

July/Baronial 2002 Inspectioneering Journal

Risk Based Inspection (RBI) analysis is a powerful tool that all of us tin utilize to assist with the circuitous issues of risk. The opportunities for application are exciting and open the door for new ways of conducting business concern and focusing resources....

May/June 2002 Inspectioneering Journal

Take chances-Based Inspection (RBI) is an emerging technology available to plant engineers and managers as they utilize run a risk directed activities to prioritize piece of work and bachelor resources for equipment management. This newspaper describes the learning of highly...

March/April 2002 Inspectioneering Journal

The American Petroleum Found Recommended Practice for Hazard Based Inspection, RP 580, is expected to be bachelor for purchase in early on May 2002.

November/December 2001 Inspectioneering Journal

A typical risk based inspection (RBI) analysis should include by inspection results, tempered by confidence in those results. For instance, API's (American Petroleum Plant) RBI methodology and software when calculating the likelihood of failure...

May/June 2001 Inspectioneering Journal

This is a summary about RBI application to plant utility boilers in a liquefied natural gas constitute with a design life of xx years, now 27 years old.

March/April 2001 Inspectioneering Journal

With the publication of API RP 579 For Fitness-For-Service and the planned publication of API RP 580 for Gamble Based Inspection in 2001, these technologies volition find increasing application in maintenance and inspection planning.

September/October 2000 Inspectioneering Periodical

In office ane of this series the importance of keeping the RBI process as simple as possible was stressed. Software, consequence and likelihood issues were covered. Consequences were handled straight while likelihood issues were covered in discussion...

July/August 2000 Inspectioneering Journal

Hundreds of risk based inspection analyses accept been completed by contractors and owner users worldwide, by now. Much is beingness learned as the various approaches gain acceptance. This editorial is only one perspective congenital upon the experiences of...

March/April 2000 Inspectioneering Journal

Ii API projects are co-sponsoring an effort to develop a adventure based inspection (RBI) method for atmospheric storage tanks (AST). Ane of the projects is the long standing RBI project that is developing RBI methods for all types of pressure...

Jan/Feb 2000 Inspectioneering Periodical

Part 1 provided a review of RBI for pressure level vessels and pipe and an introduction to application of RBI to rotating equipment and the differences between approaching the two different types of equipment. As promised, Office 2 will delve more deeply...

November/December 1999 Inspectioneering Journal

Risk based inspection, RBI, is a method currently changing how corporations view their maintenance programs. Application of a systematic analysis process that focuses on the likelihood of a given failure and the upshot of this failure happening...

November/December 1999 Inspectioneering Journal

Here are some of my observations based on numerous discussions with owner users and interest in over thirty projects. This learning is from plant operators who accept taken the RBI "plunge", after they have had time to call up about their decisions and...

September/October 1999 Inspectioneering Journal

There are many analysis tools bachelor in the market place that lay hold of the "RBI" claim. I wanted to bring you lot, the reader, "upwardly to speed" on some of the available technology based on my experience as an RBI project managing director, customer manager and member...

September/October 1998 Inspectioneering Journal

I have observed through literally hundreds of discussions and reading numerous articles on risk-based approaches that at least one potential business pitfall is appearing when owner-operators choose to begin with a "Level 1" (very qualitative)...

September/Oct 1998 Inspectioneering Journal

Inspection to determine mechanical integrity is of import to verify that equipment is suitable for intended use, i.due east. to forbid or minimize the consequences of catastrophic releases of toxic, reactive, flammable, or explosive chemicals as required...

May/June 1998 Inspectioneering Journal

The API Subcommittees on Inspection and Pressure level Vessels & Tanks are ever vigilant in keeping up with current trends and state-of-the-art applied science for in-service inspection of force per unit area vessels, process pipage, and aboveground storage tanks. One...

January/February 1998 Inspectioneering Journal

At that place is a potential for misconceptions about terms used regarding hazard by non-risk management professionals. Understand that some risk is unavoidable. We can attempt to minimize risk to any extent desired, only without an constructive procedure that...

September/October 1997 Inspectioneering Journal

The amount of serious questions regarding the various applied science options for implementing an constructive RBI programme is growing by leaps and bounds. I, for one, have seen many forms of what various organizations refer to as RBI. Remember that in that location...

March/April 1997 Inspectioneering Journal

The API Commitment on Refinery Equipment (CRE) has chartered a task grouping to develop an API recommended practice (RP 580), which will detail all the vital aspects of Hazard-Based Inspection. This standard will non detail or advise whatever one specific...

March/April 1997 Inspectioneering Journal

Our business paradigm is going through tremendous changes, equally most of our readers tin attest to. Look at the mega-mergers looming and happening in the petroleum business along with the tight margins about of them operate on.

November/Dec 1996 Inspectioneering Periodical

Three levels of risk based inspection have been developed by the API sponsor group. Level 1: Qualitative RBI which utilizes a step-by-step workbook to rank entire process units or procedure systems into a 5 ten five risk matrix...

September/October 1996 Inspectioneering Journal

In the Jan 1995 effect, I introduced the concept of Risk-Based Inspection (RBI) beingness adult by an API (American Petroleum Institute) projection. This article is an update and status report on that project, which now has 20 sponsor companies,...

March/Apr 1995 Inspectioneering Journal

Many promising advances are being made in inspection technologies, today. Some are going to provide opportunities for companies to maintain and increase equipment mechanical integrity, quite mayhap at lower costs.

Glean Lean: How To Use Lean Approach In Service Industries?,

Source: https://inspectioneering.com/tag/risk-based+inspection

Posted by: lambertthowenty.blogspot.com

0 Response to "Glean Lean: How To Use Lean Approach In Service Industries?"

Post a Comment